Well Manager® 210

Well Water Booster Pump System

Features | Specifications | Warranty

Brochure| Reviews

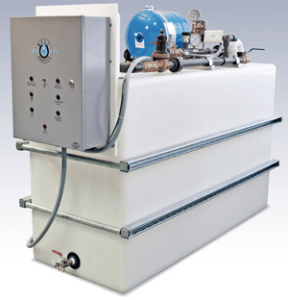

Our easy-to-install Well Manager 210 well water booster pump system enhances the yield (well recovery rate) of your well by extending your water storage capacity. Unlike a larger pressure tank, which is often recommended in the field, the Well Manager 210 unit continually draws from your well in the off times to replenish the water you’ve used, resulting in increased yield and consistent water pressure.

Well Manager eliminates the worry and inconvenience associated with waiting for your well to recover when you’ve run out of water.

The Well Manager 210 is available in three models designed to accommodate your specific space requirements while providing the same solution for your low-yielding well. The only difference in the models is the physical orientation of the equipment. Please see our Specifications table for a dimension comparison.

The Well Manager 210 comes with an easy-to-follow manual for do-it-yourself installation and set up.

Well Manager 210 CPV

Well Manager 210 CPH

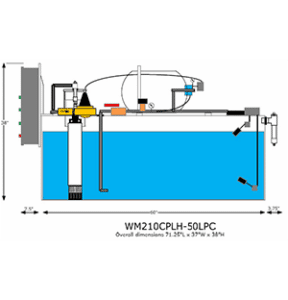

Diagram of the Well Manager 210 CPLH

Features

- Complete turnkey Well Management System for wells that produce as little as 1/10th GPM

- Easy to install: slide into place, pipe inlet, outlet, make wiring connections and turn it on

- Provides consistent pressure every bit as impressive as city water

- Remarkably quiet

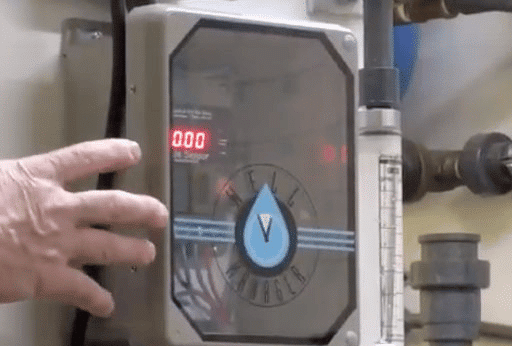

- Well Manager UL Listed control panel for 1 or 2 wells, built to industrial standards and low maintenance

- All penetrations water tight

- Low-water cutoff to protect pressure pump

- Flow Detector to protect well pump

- Digital timing control to protect well from over pumping

- Tank level controls pass NSF 61 Potable Water

- Pipe and Fittings NSF 61

- StaRite 10 GPM pump with 1 year warranty provides great pressure

- Overfill shutoff with manual reset stops overflows

- Systems with 230V pressure pump: two 230V 20 Amp circuit, one 115V 15 amp circuit

- Patented in the U.S. and Canada

- Rectangular Storage Tanks of PE resin meeting FDA regulation 21 CFR 177.1520 © 3.1 and 3.2, extra heavy walled tanks made to last

- All field wiring connections by wire nut in one box

- Service or replace pump without draining tank

- Installation, set up, and maintenance manual

- Many options – Odor removal, pump upgrades, additional storage

| Specifications | |||

|---|---|---|---|

| Description | 210 CPV | 210 CPH | 210 CPLH |

| Weight | 300 lbs | 300 lbs | 300 lbs |

| Length | 45 inches | 69 inches | 69 inches |

| Width | 26 inches | 39 inches | 37 inches |

| Height | 74 inches | 49 inches | 39 inches |

| Horsepower | 1/2 hp | 1/2 hp | 1/2 hp |

| Voltage | 120 | 120 | 120 |

| Max Amps | 11 | 11 | 11 |

| Hertz | 60 | 60 | 60 |

| Max Flow Rate | 10 GPM | 10 GPM | 10 GPM |

| Min. Incoming Pressure | n/a | n/a | n/a |

| Max. Output Pressure | 50-70 psi / 60 psi constant | 50-70 psi / 60 psi constant | 50-70 psi / 60 psi constant |

| Gallons Per Minute | 10 GPM | 10 GPM | 10 GPM |

| Inlet Diameter | 1 inch | 1 inch | 1 inch |

| Outlet Diameter | 1 inch | 1 inch | 1 inch |

| Effective Water Storage | 195 gallons | 185 gallons | 175 gallons |

Warranty

This product is warranted to be free of defects in materials and workmanship for a period of one year from the date of original purchase. Individual components may be warranted by each component manufacturer for periods longer than one year.

Your Title Goes Here

Do I have low water pressure because my well is failing?

Some factors that can cause low pressure, which should be investigated, are the age of your pump; over-pumping due to increased demand; a clogged filter; faulty equipment. Of course, the condition of the aquifer that feeds your well can also have an impact on your water pressure and volume.

The availability of water from your well can be impacted by various factors, too: rainfall or the lack thereof; changes in rock structure due to ground shifts; your neighbors drawing water from the same source for pool filling, irrigation, or livestock – all these can impact your water well.

The Well Manager products are designed to resolve low water pressure and to increase water availability even if you have a low yield or low producing well! Contact our well water specialist today to discuss your specific issues and questions.

Well Manager Reviews

Interested in reading more about the Well Manager equipment?

Visit the Well Manager – additional information page for future information.

Questions? We Can Help!

Phone: (800) 211-8070 or use our online Form, and a Well Manager rep will respond in a timely manner.

Related Products

Want to Know More About How to Increase Water Pressure From a Well? Check Out Our Additional Products!