Well Manager®

for use with well water

Enhance Your Well's Yield and Water Storage

The Well Manager® 210 is an easy-to-install well water timed collection and consistent output pressure pump system for low-yield wells.

The Well Manager® gently sips water from your well, with adjustable rest periods to replenish the water consumed. This provides large volumes of stored water to be utilized as needed.

Built for wells yielding 0.25 gpm or more, Well Manager® protects your well pump, preserves your aquifer, and provides consistent output pressure.

A Lifetime of Reliable Water, a Lasting Investment! - 100% Guaranteed Results

Well Manager® System Overview

Engineered Where Others Fall Short

See How Our Systems Changed Lives

“Very pleased with my recent Well Manager purchase. I had a well scare where I ran out of water and almost blew out my well pump. I researched various well options and came across Well Manager. After multiple conversations with Well Manager, I decided to pull the trigger. It took about 3 hours for the installation and the system has worked flawlessly since it went in about 3 weeks ago. I have better water pressure and most importantly I can take a shower, run my dishwasher and washing machine all at the same time and never have to worry about running out of water. I highly recommend Well Manager for solving your well headaches.”

Bob Halpern

Request a Quote for Your Custom Water Solution

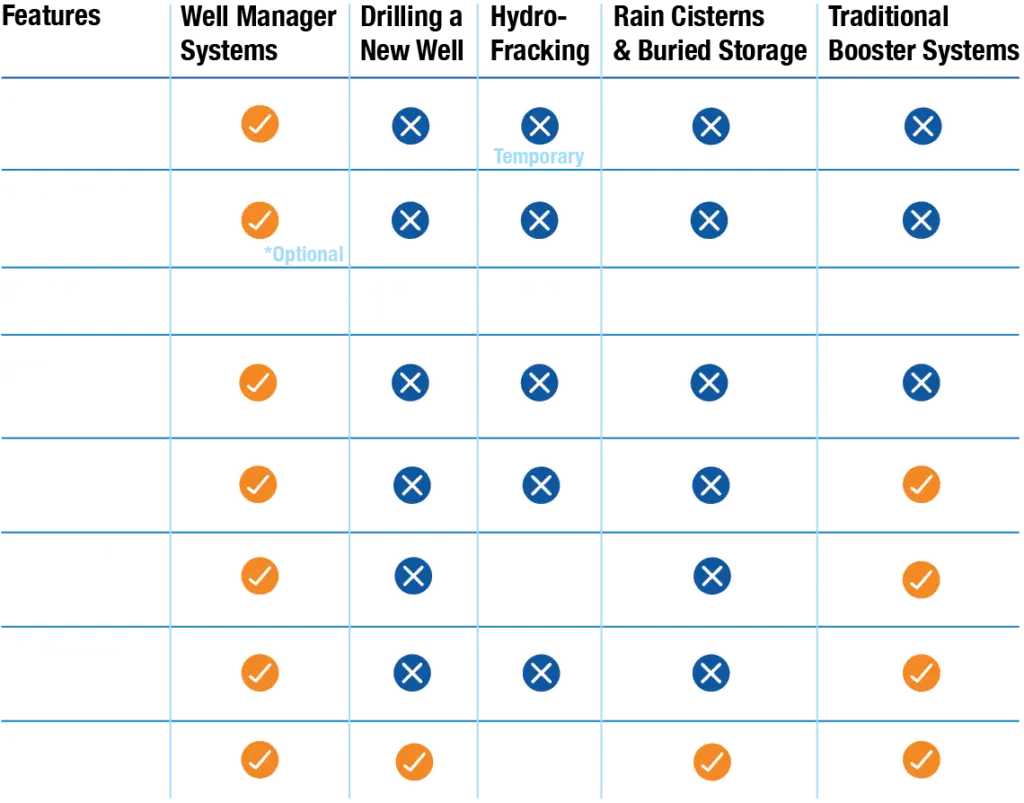

Why Choose Well Manager®?

More Than Just a Water Tank

Timed Water Collection

Optimizes Well Yield

- Collects water from low-yield wells at timed intervals set by the smart control panel

- A manual ball valve is used to throttle flow from the well, maintaining safe and steady input

- A low-pressure transducer monitors real-time well conditions to confirm water availability

- The system stops fill cycles if pressure drops too low, helping prevent dry-run

- Enables precise control of water collection based on your well’s recovery rate

Smart Control Panel (1, 2, or 3 Wells)

Easy To Monitor & Manage

- Manages the full system: water collection, storage, and pressurized delivery

- Monitors inputs from float switches and the low-pressure transducer

- Runs timed fill cycles and protects pumps from overuse or dry-run conditions

- Built with industrial-grade relays, timers, and logic circuits for reliable, automated operation

- Includes clearly labeled status indicator lights for diagnostics

- Hand-Off-Auto switch allows manual override and service testing

Tank Water Level Management

Automated Water Level Protection

- Uses high and low float switches to track tank volume and manage collection timing

- Signals the control panel to pause water intake when full

- Complements the timed fill cycle by providing real-time input on storage status

- Works in coordination with the motorized ball valve to stop flow when the high float is engaged

Overfill Shut-Off

Homeowner Protection

- Built-in logic shuts off water intake when the tank is full

- Prevents accidental overflow and protects the home or mechanical space from flooding

Run-Dry Protection (Well Side)

Over-Pumping Protection

- Uses the flow detector and control panel logic to pause fill cycles when no water is available

- Protects the well pump from overheating or burnout

- Essential for safe operation of low-producing or seasonally sensitive wells (Protects Well Health)

Water Storage

210+ Gallons

- Provides a reserve of collected water for consistent availability

- Ensures steady supply during peak use, outages, or dry spells

- Critical for homes with limited well production and high water demand

DAB VFD Pump(s)

Consistent Output Pressure

- Delivers quiet, efficient water pressure from the storage tank to the home

- Automatically adjusts to flow demand for consistent pressure across all fixtures

- Ideal for maintaining pressure during showers, laundry, irrigation, and more

Smart Flow & Delivery Path

Intelligent Water Flow Control

- Incoming Water: Incoming Water: Pulled from the well via a flow detector and electric actuated ball valve

- Outgoing Water: From storage tank to home via DAB VFD booster pump

- The system coordinates intake, storage, and delivery to support low-yield wells with consistent pressure

Plug & Play

Electrical Setup – Dedicated Circuit Plug

- Plugs into a dedicated, breaker-protected outlet for safe and stable operation

- External DAB pumps connect directly to the outlet on the Well Manager® control panel

- Dedicated 115V 15 AMP & 220V Well Source

- Keeps electrical loads isolated and protected for long-term reliability

Learn More About Well Manager® Systems

Get the Details on Well Manager® Systems

Well Manager® Flexibility – Built for Any Space

Space Flexibility

Vertical, Horizontal, Low Horizontal

Expandable Storage

Add 210-Gallon Tanks

Custom Pump Options

Internal, External, Dock-Mounted

Learn More

Well Manager® Specs page.

Well Manager® 210 Two Tank Vertical System with an External DAB E.sybox Mini 3 Pump

Well Manager® 210 Two Tank Vertical System with an External DAB E.sybox Pump

Well Manager® 210 Horizontal System with an External DAB E.sybox Mini 3 Pump

Well Manager® 210 Low Horizontal System with an External DAB E.sybox Mini 3 Pump – 1

Well Manager® 210 Low Horizontal System with an External DAB E.sybox Mini 3 Pump – 2

Well Manager® 420 Two Tank Horizontal System with an External DAB E.sybox Mini 3 Pump – 1

Well Manager® 420 Two Tank Horizontal System with an External DAB E.sybox Mini 3 Pump – 2

Well Manager® 420 Two Tank Horizontal System with an External DAB E.sybox Mini 3 Pump – 3

See Where Well Manager® Is Making a Difference

These real-world installations showcase how our systems bring reliable water solutions to homes and businesses.

Financing Options to Make Well Refurbishment More Affordable

To make reliable water solutions more accessible, we offer financing through trusted Nonprofit Partners and Synchrony.

Build Your Own System – The Modular Kit is Here

Same performance, more flexibility. The Modular Kit gives you everything but the tank, so you can save money, reduce freight costs, and use a tank that fits your space and budget.

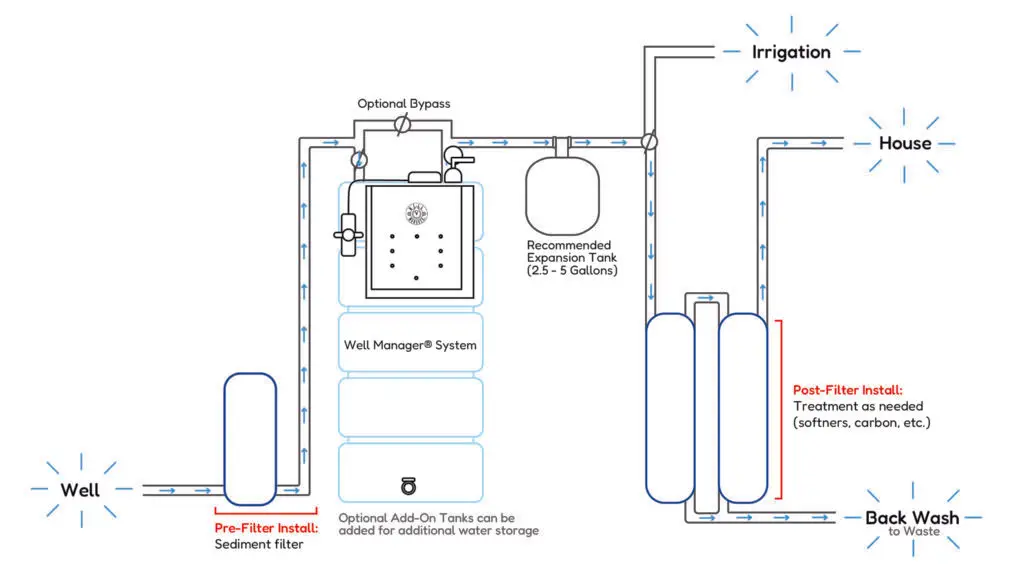

Where Well Manager® Fits in Your Water Line

Diagram highlights pre- and post-filtration recommendations for a complete setup.

Installation Note: An expansion tank (2.5–5 gallons minimum) is recommended on the pump’s outlet side to prevent short-cycling. With a Well Manager® system, the existing pressure tank can often be reinstalled after the system to serve this purpose. Otherwise, a separate expansion tank should be added.

Various Tank Sizes & Configurations

Warranty

This product is warranted to be free of defects in materials and workmanship for a period of one year from the date of the original purchase.

Individual components may be warranted by their respective manufacturers for periods longer than one year.

Request a Quote for Your Custom Water Solution

Fill out the form below, and our team will reach out via email or phone to ensure you receive the most personalized and accurate quote possible.

Other Products