Many people get their drinking water from fresh water aquifers but few understand how or why you get pure water by simply drilling a hole in the ground and fewer still have any idea how the operation of their water system can affect the quality and sustainability of the water supply. In fact, aquifer/well relationships can be much more complicated than they appear and much of the damage we do to them results from actions that “seemed like a good idea at the time.”

How It All Works

The water well is your personal connection to nature’s infrastructure, the local aquifer. This connection means that millions of gallons of water are available for your use but the rate at which it flows into your well is determined by the makeup of the ground in which the well is constructed and the way that you operate it. That’s right, the way you operate the well can determine the quality and quantity of the water you get and the length of service the well will provide.

Most people know someone who has had to drill a new well because the old one “went dry.” The cause was a complete mystery and the fact that the driller was able to drill another good well only 50’ away raised no questions. The person with the dry well was just glad to have water again.

Had they stopped to think about it they might have wondered why a new hole so close found water when the one just over there was now dry. Obviously the aquifer still has water in it and the new well probably filled up just as high as the old one did when it was new, so what happened?

If theirs was a low yield well, chances are it was the way the well was operated that caused it to “run dry.” Conventional pumping systems remove water from the well until the end use is satisfied, whether that end use is your shower or a storage tank that needs filling. In a slow or low yield well, the water column is constantly being drawn down when demand for water exceeds the rate at which it flows into the well. Pumping water out of a well faster than it comes in is called over pumping. Periods of extended over pumping increase the rate at which water travels through the ground immediately around the well drawing in sediment that adds cloudiness to the water and may eventually clog the cracks that are the arteries in your water delivery system thus severing the well’s connection to the aquifer.

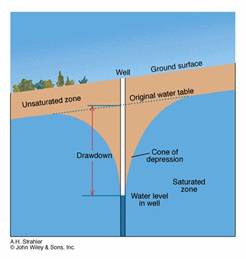

Every well that is being pumped has some influence on the surrounding area. When a well is pumped, the nearby water starts flowing in immediately, draining the ground around the well while the more distant water flows in to replace that which entered the well. This difference in rate of travel results in a cone shaped depression in the aquifer around the well that gets shallower as you get further from the well, growing in size the longer you keep the well level drawn down.

Once pumping ceases the cone of depression slowly fills in as water from a distance moves toward the area of lower pressure. Because this cone influences the movement of water through the aquifer it is said to create a “zone of influence” which affects the way water flows through the geology in the vicinity of the well.

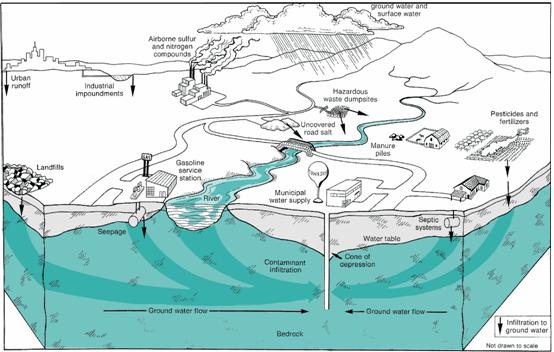

When a well withdraws water slowly from an aquifer the only contaminants that are likely to affect it are those directly upstream from the well but over pumping increases the radius of influence that a well creates – its zone of influence – and can even reverse the direction of natural flow in the aquifer. The influence created by pumping hard draws water from 360 degrees around the well, bringing contaminants such as brine from nearby bodies of salt water, nitrates and fertilizers from adjacent farm land, surface water from streams or even leakage from underground storage tanks to the last place you want it; your water supply.

When a well is pumped more slowly we benefit from the aquifer’s natural tendency to dilute contaminants and when we pump too hard we cause the contaminants to be concentrated and drawn to the well.

The Lasting Effects of Over Pumping

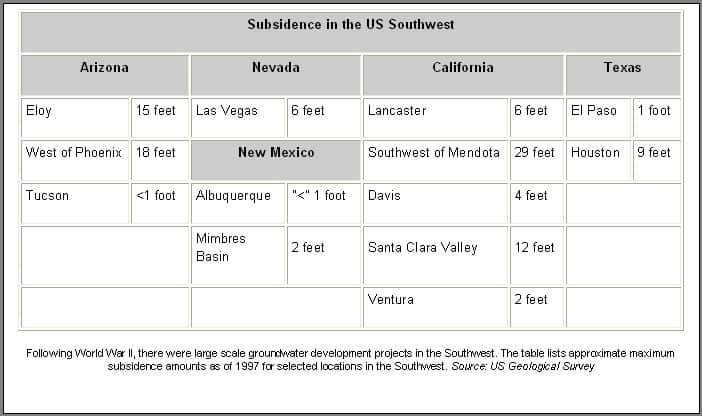

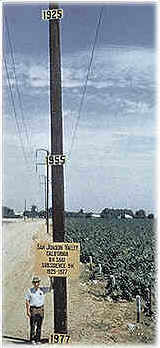

The negative effects of over pumping are cumulative and lasting. When you over pump an aquifer the result can be the spreading of contamination or even land subsidence. Subsidence is the settling of ground and may be caused by a number of natural occurrences but more than 80 percent of the subsidence in the United States is related to the withdrawal of ground water1. When land subsides, it is compacting. The spaces in the ground are closing and therefore the ground lowers or subsides. If you look at the definition of an aquifer2 you see that it is the spaces that contain the water. Once those spaces disappear the aquifer’s ability to store water is reduced forever. A long rainy season or good snow melt is not going to recreate voids that have closed.

When a well is over pumped, water is withdrawn faster than it is coming in and the water level in the well drops dramatically as the geology around the well drains. The longer this goes on the more widespread the dewatered area is. When the nearby cracks and voids are emptied of water they may collapse if they were not self supporting.

This phenomenon is most obvious in hydrofractured wells that suffer from diminishing yield. If you review a description of hydrofracturing3 you will see why. Though many hydrofractured wells show an increase in production, it is often not enough to take them from low yield to great producers. When a low yield well is pumped by conventional means there will be times when it is pumped quite low. If the level in the well is reduced enough that the fractures opened by hydrofracting are out of the water and draining they can suffer from subsidence. The water was the wedge that created or widened the fracture and has been helping hold it open. Once the wedge is removed the fracture can slowly close back up decreasing yield and increasing the frequency of out of water events. The end result is that, over time, you can end up right back where you started. This is a phenomenon which those who hydrofracture oil and gas wells understand and is the reason that some inject sand with the water used in that process.

Even in the short term over pumping can result in decreased well yield. Dewatering is what causes the cone of depression around a well. The longer this goes on the larger the cone (dewatered area) becomes. The deeper and wider the cone, the smaller the interface between the well and aquifer and the lower the well yield will be. This should not come as shocking news as it is the purpose of a dewatering operation; to lower the groundwater level and decrease the inflow rate so that an area can be excavated. Whether on purpose or by accident, the result of over pumping is dewatering and this is not an efficient way to operate a well intended as a continuing source of water.

How Can I Get Safely More Water From My Well?

Recently a gentleman approached us asking if we could get more water from his wells. He had two 900’ wells that fed a 4200 gallon buried storage tank which he used to supply an irrigation system. The well pumps ran continually trying to keep up with the irrigation system’s needs but were failing to do so. When we suggested that he would get more water by pumping less he thought we were insane. It took a great deal of convincing but in the end he bought a Well Manager duplex well control system, a PumpChamber for the 4200 gallon tank and a Consistent Pressure Module for the irrigation system. The end result was that the 4200 gallon tank now fills in 1/3rd the time and the wells are easily keeping up with the irrigation. Now, you are wondering, how this could be?

The explanation can be found in a combination of factors. First, the well pumps are delivering more gpm now because the wells are running nearly full and they do not have to lift the water from 800 feet. Second, the well yield is increased because he is no longer dewatering the area and reducing the well’s interface with the aquifer. Of course, since the pumps run a lot less, his electric bill is reduced dramatically.

This demonstrates that you get the most from a well when withdrawals are in step with the rate at which the aquifer can transmit water. When pumping is in excess of the transmission rate the operation changes from water harvesting to dewatering and well yield begins to decline.

Over pumping threatens the well’s longevity not only through subsidence and dewatering but also through mineral or biological buildup. Wells fed by fractures, those that dribble in through tight shale or those with well screens are all susceptible to loss of production resulting from buildup of mineral crust or bio-slimes. This buildup can be hastened by continually over pumping and exposing the well walls to the air. The same minerals that cause buildup on your faucet aerator or create stalactites and stalagmites in caves can build up where water comes into the well bore reducing the well yield and eventually seal it off from the aquifer.

Arsenic in groundwater has been a hot topic for some time. The current federal limit in drinking water is 10 ppb (parts per billion) but some local jurisdictions have already adopted a lower 5ppb limit as the EPA has stated their intention to lower the maximum contaminant level again. New Jersey and other states now require a water test when you sell your home. If there is too much arsenic in the water, treatment is required and can be expensive.

Arsenic exists in nature in combination with other elements like iron or sulfur in the form of various minerals. It is the oxidative breakdown of these minerals that releases the arsenic into water. Natural changes in the water table can result in mineral oxidation but over pumping can make the situation worse. Over pumping a well exposes the geology in the cone of depression to the air. If there are arsenic-bearing minerals in that geology, arsenic can be released by oxidation and picked up in the water when the cone of depression fills back in after pumping ceases. Many experts now suspect that unacceptable levels of arsenic in well water are another unintended consequence of over pumping.

It is this reality that has led Dave Johnson and Tom Riewe of the Bureau of Drinking Water and Groundwater, Department of Natural Resources, Madison, Wisconsin, to recommend the testing of well water for arsenic every couple of years4. Other agencies around the world are recognizing that over pumping is the most common cause of premature well failure5. Some have rewritten their groundwater law to reflect this6.

The Issue With Current Systems

Unfortunately, the most commonly installed system to deal with low-yield wells is a cistern-type system. Most of these cistern and similar above-ground tank systems control the well pump with a tank full float. When the tank is not full the well pump is turned on to replace the water used from the tank. The float keeps the well pump running until the tank is refilled but on occasion, when use is heavy and ongoing, there may not be enough water stored in the well to refill the tank and keep up with ongoing use.

To prevent the well pump from running when the well is empty most contractors install a motor protector with a timed reset so that the pump is turned off for a time while the well refills. Some people call these “well timers” but they were designed to protect well pumps from burnout due to dry running and are not a good operating mechanism to collect water from a low yield well because they only turn the well pump off AFTER the well is emptied. Constantly over pumping the well like this reduces well yield, increases the likelihood the well will be frequently pumped down, results in attracting dirt and contaminants and contributes to its early demise through mineral encrustation, bio-fouling, subsidence, and all the other factors discussed above. Why? Because the well must be pumped empty for the motor protector to shut the pump off. The well ends up being operated like a sump pump pit as it is emptied time and again until the cistern is full.

Well Manager was designed to work as it does because we realized early on that over pumping was a major cause of well failure and that you could actually get more from a well by pumping more slowly. Well Manager is the only “off the shelf” well water harvesting system that works to balance your water needs with the natural hydrologic cycle by getting in step with the rate at which nature delivers water to your well. The Well Manager® system is designed to be flexible so it can deal with a well yield that varies from season to season without over pumping while delivering constant, dependable service to your home, church, or school.

If the rate of flow into your well is 1 gallon per minute (GPM), then over the course of a 24-hour or 1440 minute time span it is capable of delivering 1440 gallons of water or enough to supply three to four times the amount of water to satisfy a household of four. In order to collect this much water from a well, however, you must keep it producing. Most wells produce only a fraction of their potential because standard pressure tank systems only withdraw water from the well when someone is using water and so allows them to be at rest most of the time.

The Well Manager® system, patented in the US and Canada, collects smaller amounts of water at regular timed intervals whether you are using water or not and is adjustable so it is possible to collect the entire production of a well or to limit the amount of water that can be withdrawn. Managing a well in this way means that it can be kept producing as long as necessary while maintaining it in a nearly full condition. This reduces the well’s adverse influence on the aquifer, the likelihood that debris and contaminants will be drawn to it, reduces the risk of releasing arsenic from minerals by oxidation, eliminates the damage to the feeding fractures caused by continually over pumping and minimizes the likelihood that air drawn into the well will cause contamination there.

The system’s atmospheric storage tank has a filtered air breather and is designed to handle peak demand; water is pumped from the well column at precisely timed intervals, generally 1, 2 or 3 times per hour. During each harvesting, the pump is run for only a few minutes and the interval between pump activations is more than adequate to keep the motor from overheating. By setting the Well Manager to retrieve water in this manner, the water level recovers between each pump interval and remains fairly high in the well bore, minimizing the cone of depression and all of the problems associated with it.

Maintaining the well in this condition throughout the operating cycle reduces the amount of air drawn in dramatically and the rate at which water travels through the ground. Slower, more natural water movement lowers the amount of oxygen in the water and reduces or eliminates the debris that faster-moving water often brings with it. As a result, many Well Manager customers find that their water clarity improves dramatically and that the contaminants revealed in their water tests is reduced over time.

A Well Manager® pumping at nature’s pace brings you more, better quality water and provides you with the satisfaction of knowing you have the most environmentally sensitive water harvesting system available anywhere!

Contact us today at 800-211-8070 or fill out a form to learn more about the Well Manager solution.

Resources:

- Galloway, D.L., Jones, D. R., and Ingebritsen, S. E., eds., 1999, Land subsidence in the United States; U.S. Geology Survey Circular 1182, 177p. https://pubs.usgs.gov/circ/circ1182/

- An aquifer covers many square miles and is composed of spaces filled with water in the various layers of material beneath the ground. In one area there may be sand or gravel deposits, in another the shale may contain many fractures, and in still others dense rock formations may have relatively few spaces (voids) in the form of fractures created by the cooling and heating of the earth’s crust. These cracks and voids fill with water that soaks down through the ground and together form a water-bearing stratum called an aquifer.

- Hydrofracturing – Water is pumped into the well bore quickly building pressure until a sudden drop in pressure occurs indicating a breakthrough. If the pressure was high enough, the rock pressure is overcome, the rock is cracked and a fluid-filled fracture is opened up. The overburden can actually be lifted up and pumping in more fluid can extend the crack. [The overburden is the rock layers above the fractured rock.] It is not necessary to have very large cracks to increase the permeability dramatically (tenths of an inch or less)

- WaterWells_module7.pdf (alberta.ca) – Troubleshooting Water Well Problems on the Government of Alberta website